Frequency inverters

Frequency inverters

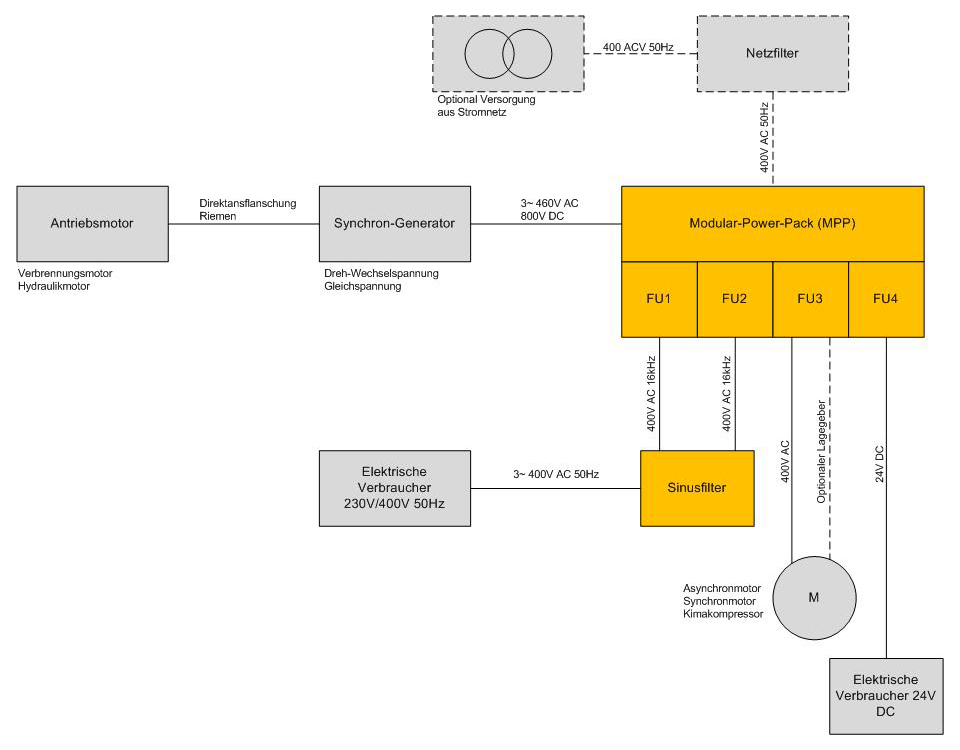

Mobile power generation must solve a basic problem: The input energy from the original drive or engine varies with the speed of the vehicle or the engine rpm, but the electrical frequency remains constant. The magic word for solving this core problem is VSCF—Variable Speed Constant Frequency.

The electronic GTS Inverter Technology ensures a constant output frequency. Our MPP series (Modular Power Pack) variable frequency inverters are the high-tech solution specifically for mobile applications. The power range can be selected individually for controlling power generation while driving, parked, or applications that require both.

Its compact and modular design allows the GTS‑MPP to be integrated into your specific overall system. Even very complex complete systems can be controlled and regulated through flexible arrangement of the individual modules, for a simple and compact solution.

Connection to your overall system enables not only continuous monitoring of the individual modules and consumers, but also rapid diagnostics in case of failure. Redundant architecture makes it possible to continues to operate the system in emergency mode even in case of a single defect.

The MPP series variable frequency inverters “chop up” the variable DC voltage produced by the generator into three-phase AC voltage at a constant frequency and voltage. A downstream sine-wave filter then produces sinusoidal AC voltage from the “chopped-up” DC voltage again.

Depending on the application, our GTS variable frequency inverters consist of up to 5 different modules (master module, fan, rectifier, variable frequency inverter, and sine-wave filter).

Features:

- Modular design from individual power and functional modules

- Automotive connection terminals available

- Power classes available: 10 kVA, 20 kVA, and 30 kVA

- Sine-wave filter can be connected in parallel to boost power

- Automotive construction with protection class IP54 (later IP69K)

- Flexible expandable

- Extended temperature range

- High mechanical loads

- Vibration-resistant

- Durable and maintenance-free

- Number of variable frequency inverter modules is scalable (up to 4 modules)

Advantages:

- reduces fuel consumption

- Reduction in noise emissions

- Perfect efficiency level

- maintenance-free

- Suitable system solution with modular design

- Increased power and redundancy with modules connected in parallel

- Self-protecting system

- Short circuit protection

- Can be used in rough environments (highly resistant to vibrations and temperature)

- Individual parameterization

- Very little cabling required

Areas of application:

- Intelligent energy distribution systems

- Speed control for motors and compressors

- Torque/speed control for motors

- Frequency correction

- Reducing start-up power

Accessories:

- Sine-wave filter

- Transformers forming neutral conductors

Technische Daten Modular Power Pack (MPP):

| Modules: | |

| Rectifier for AC power supplies | 0 – 100 A |

| Frequency inverters | 10, 20 and 30 kVA |

| Intermediate condensers | as needed |

| Charging/braking module | as needed |

| Electrical data: | |

| Supply voltage | 3~ 0-480 V AC |

| 0-800 V DC | |

| Auxiliary | 24V DC |

| Output voltage | 3~ 0-440 V AC |

| Output frequency | 0-400 Hz |

| Controller/regulation: | |

| Frequency control | v/f |

| Speed control | vector |

| Torque control | on request |

| Interfaces: | |

| Bus (1x controller, 1x service/diagnostics) | CAN 2.0 A/B |

| Digital input (up to 5x) | 0/24V |

| Relay outputs (up to 5x) | Normally open contact (250V/2A) |

| Analog input (1x) | 0-10V or 0/4-20mA |

| Mechanical data: | |

| Dimensions | depend on build |

| Weight | depend on build |

| Cooling | Air-cooled |

| Passive cooling | |

| Protection class | IP54 |

| Others per specification | |

| Connection (auxiliary supply & interfaces) | plug connection |

| Connection (power) | Screw connection |

| Plug connection on request |

Do you need more information?

Register and receive GTS brochures and flyers!